Reducing Costs and Boosting Efficiency in Warehousing with Autonomous Vehicles

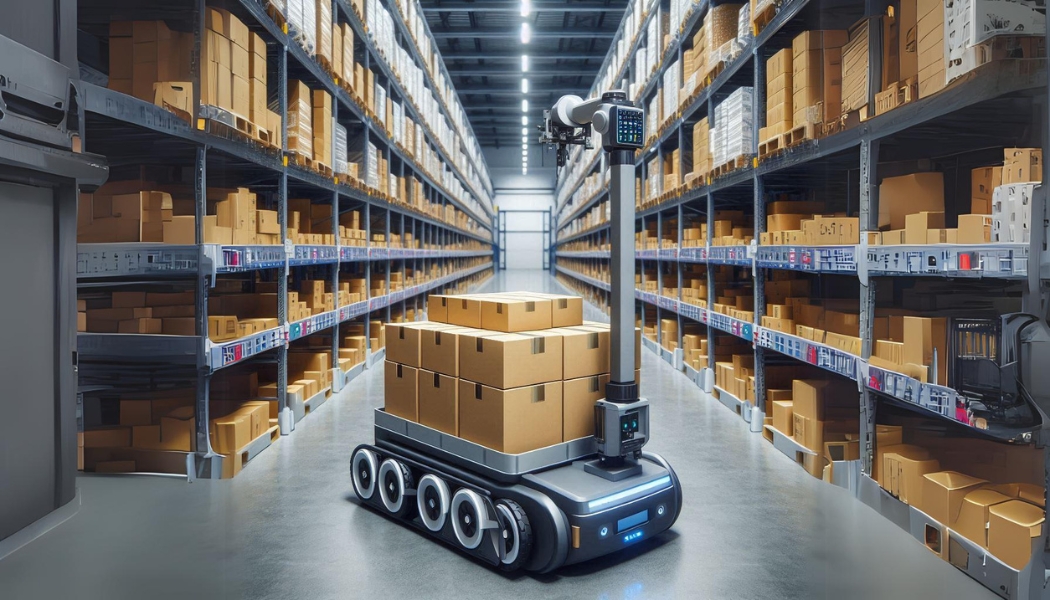

The warehousing industry has always been at the heart of supply chain operations, ensuring the seamless movement of goods and products from manufacturers to consumers. Rising expenses, the necessity of more effective space use, and growing consumer expectations for faster and more precise delivery all present difficulties for this industry, though. One exciting answer to these problems is the inclusion of autonomous cars (AVs) into warehouse activities. The autonomous guided vehicle is redefining warehouse efficiency by lowering staffing costs, maximizing floor space, and simplifying processes.

Reducing Manpower Costs

The possible cost savings of including autonomous cars in warehouse operations are among their most important benefits. For warehouses, labor is a significant cost factor, particularly in relation to repetitive tasks, including order fulfillment, inventory movement, and material delivery. Robots and self-driving forklifts are among the autonomous vehicles that can complete these jobs without human involvement, therefore lessening the requirement for handwork.

Optimizing Floor Space Utilization

Space typically limits warehouses, hence careful use of floor area is essential to maximize storage capacity and guarantee flawless operations. Conventional warehouses move products around using human labor, which can cause waste of space and inefficiency. Conversely, autonomous cars can precisely negotiate the warehouse floor, therefore optimizing the inventory arrangement and increasing storage density.

Modern sensors and mapping systems enable autonomous guided vehicle—such as automated guided vehicles (AGVs) or autonomous mobile robots (AMRs)—to negotiate warehouse conditions with little human control. These effective means of transportation for commodities from one place to another free space for improved organization. Moreover, they can operate in confined locations and smaller aisles, which is usually challenging for conventional pallet jacks and forklifts.

Increasing Order Accuracy and Speed

Accuracy and quickness rule in the fast-paced e-commerce scene of today. Consumers want fast and consistent delivery; any error in order fulfillment could cause delays, refunds, and unhappy consumers. Improving the precision and speed of warehouse operations depends much on autonomous vehicles.

Faster reaction times and more dependable service made possible by autonomous cars help warehouses to satisfy the growing needs of e-commerce consumers by means of more accurate operations.

Enhancing Warehouse Competitiveness

Including autonomous cars into warehouses not only help to lower costs and increase efficiency but also keeps competitiveness in a market going fast and digital. Companies that embrace AV technology can better fit evolving client expectations, minimize operational interruptions, and get a competitive edge over those depending on conventional, human labor-driven systems.

Apart from raising operational effectiveness, autonomous cars can enable warehouses to offer further value-added services. For instance, they can manage more frequent deliveries or smaller orders—qualities crucial for e-commerce companies handling a lot of little parcels. This capacity helps warehouses to become more flexible and sensitive to the often shifting needs of contemporary customers.

By lowering costs, maximizing floor space, and enhancing order accuracy and speed, autonomous vehicles used in warehouses are revolutionizing the sector. The adoption of AV technology offers a solution that improves competitiveness and operational excellence as companies still struggle with growing labor expenses and growing expectations for efficiency. Embracing autonomous cars helps warehouses to satisfy changing consumer needs and position themselves to succeed in the future of logistics.